An economizer is a device installed at the lower part of the boiler to recover the waste heat of flue gas. It heats the boiler feed water into the heating surface of saturated water under the drum pressure. Because it absorbs the heat of high-temperature flue gas, reduces the flue gas temperature, saves energy, and improves efficiency, it is called an economizer.

The steel pipe economizer is not limited by pressure and can be used as a boiling type. It is generally made of carbon steel pipe with an outer diameter of 32 ~ 51mm. Sometimes fins and fins are added to the tube to improve the heat transfer effect. The steel tube economizer is composed of horizontally arranged parallel elbow pipes (commonly

known as serpentine pipes).

The economizer is mainly applicable to industry and is gradually popularized in agriculture and some related industries.

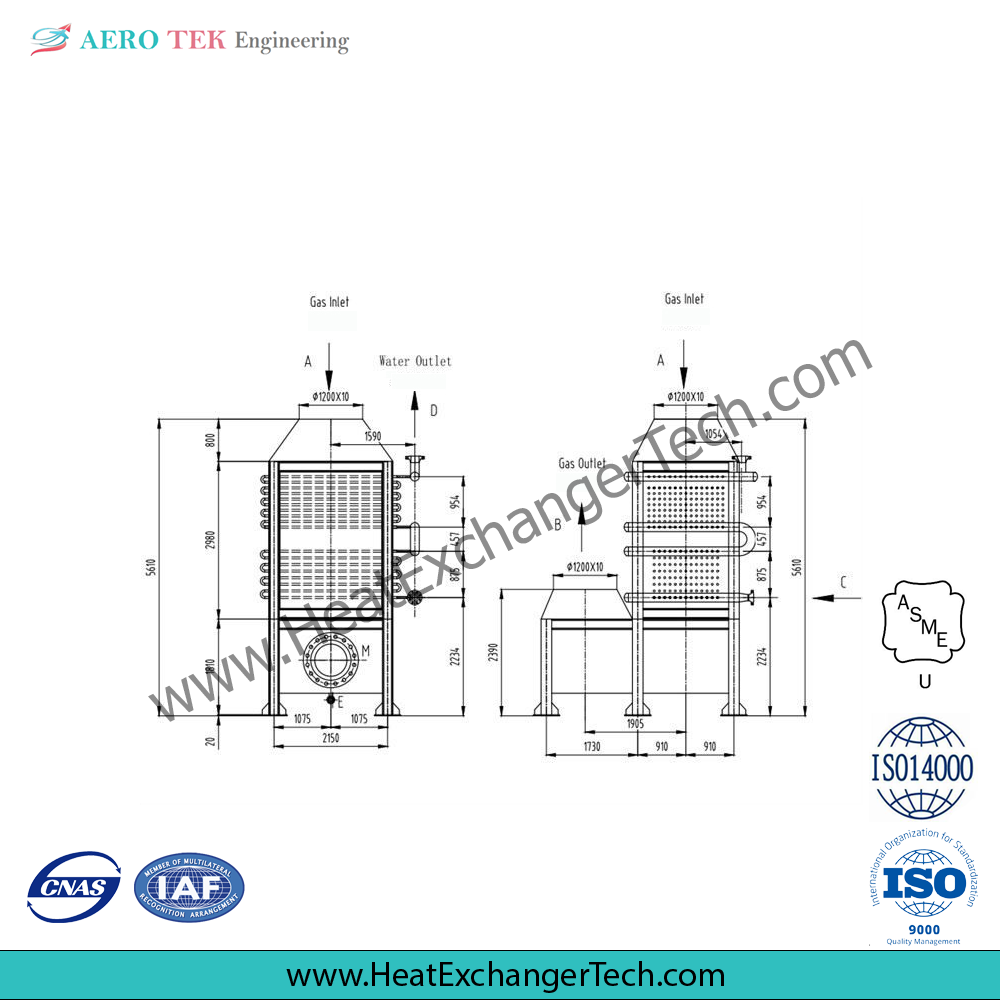

Product Name: Economizer OD: 32~51mm

Pipe Material: Carbon steel Function: Recover waste heat

Installation: Part of boiler Manufacture Standard: ASME

Classification of Economizer:

There are many ways to classify economizers, which can be classified as follows:

- According to the heating degree of feed water, it can be divided into the nonboiling type and boiling type.

- According to the manufacturing materials, there are two kinds: cast iron and steel pipe economizers. Nonboiling economizers are mostly made of cast iron, but they can also be made of steel pipe while boiling economizers can only be made of steel pipe. Cast iron economizers are mostly used in boilers with pressure ≤ 2.5MPa. If the pressure exceeds 2.5MPa, the economizer made of steel pipe shall be used.

- According to the form of the device, there are two types: vertical and horizontal.

- According to the relative flow direction of smoke exhaust and water supply, there are three types: forward flow type, counter flow type, and mixed type.

- According to the structural form, it is divided into a smooth tube economizer and a fin economizer. Finned economizer includes H-type economizer (used more) and spiral finned economizer.

- According to the form of heat conduction: direct conduction and indirect conduction.9 Direct conduction is to preheat boiler water by direct radiation of boiler tail gas; Indirect conduction is the indirect preheating of boiler water through heat-conducting medium; Since the 1990s, indirect conduction technology has developed rapidly and made great breakthroughs in technology, mainly including heat transfer oil technology patents and superconducting thermal energy-saving technology patents. Especially from the beginning of the 21st century, aerospace superconducting thermal material technology has been at the forefront of the world’s boiler energy-saving field.

The function of economizer:

- Absorb the heat of low-temperature flue gas, reduce the flue gas temperature, reduce the flue gas loss and save fuel.

- Since the feed water is heated in the economizer before entering the steam drum, the heat absorption of feed water on the heating surface is reduced, and the economizer can be used to replace some evaporation heating surfaces with high cost.

- When the feedwater temperature increases, the wall temperature difference will be reduced when entering the steam drum, the thermal stress will be reduced accordingly, and the service life of the steam drum will be prolonged.

Send Inquiry