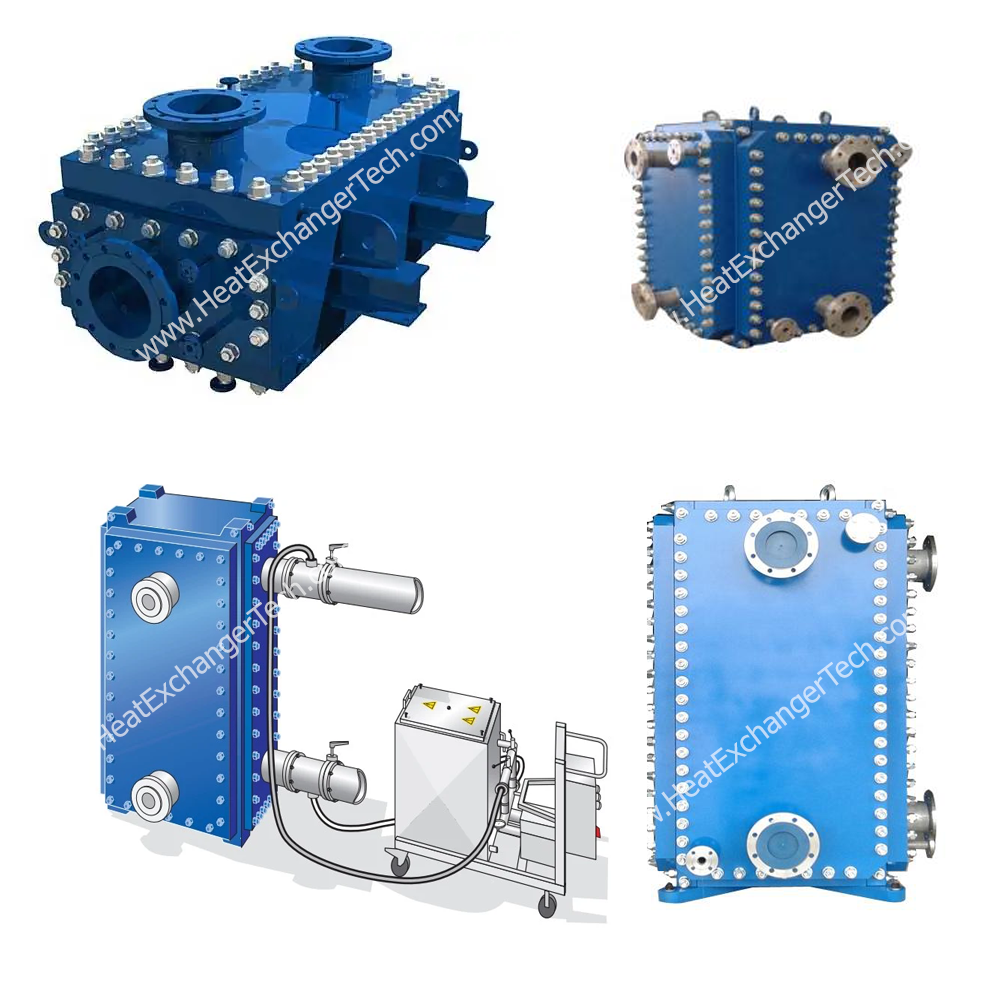

However, due to the limitations of its own structure, the use pressure of the traditional removable plate heat exchanger is not more than 2.5MPa and the use temperature is not more than 150℃. In addition, there are defects that the rubber gasket is easy to fail under high temperature and the application problems in some specific media have not been solved. Therefore, in order to improve the service temperature and pressure of the plate heat exchanger and expand its application range, we have developed and manufactured an all-welded plate heat exchanger. The heat exchanger can work normally under the extreme working conditions of working temperature 300℃ and pressure 3.0MPa.

All welded plate heat exchanger expands the application range of gasket heat exchanger and has the advantages of high-temperature resistance (maximum temperature 300 ℃), high-pressure resistance (maximum pressure 40bar), corrosion resistance, and high heat transfer efficiency.

It belongs to the inter wall heat exchanger. The structural form of the heat exchanger is that two flow channels are formed between the plates of two adjacent stations by welding. Two media with different temperatures flow through the channels on both sides of the same plate respectively. Each media channel controls the flow area, i.e. flow length, through the split partition, so that the high-temperature fluid transfers heat to the low-temperature fluid through the plates, So as to achieve the purpose of heat exchange

Send Inquiry