Product Details:

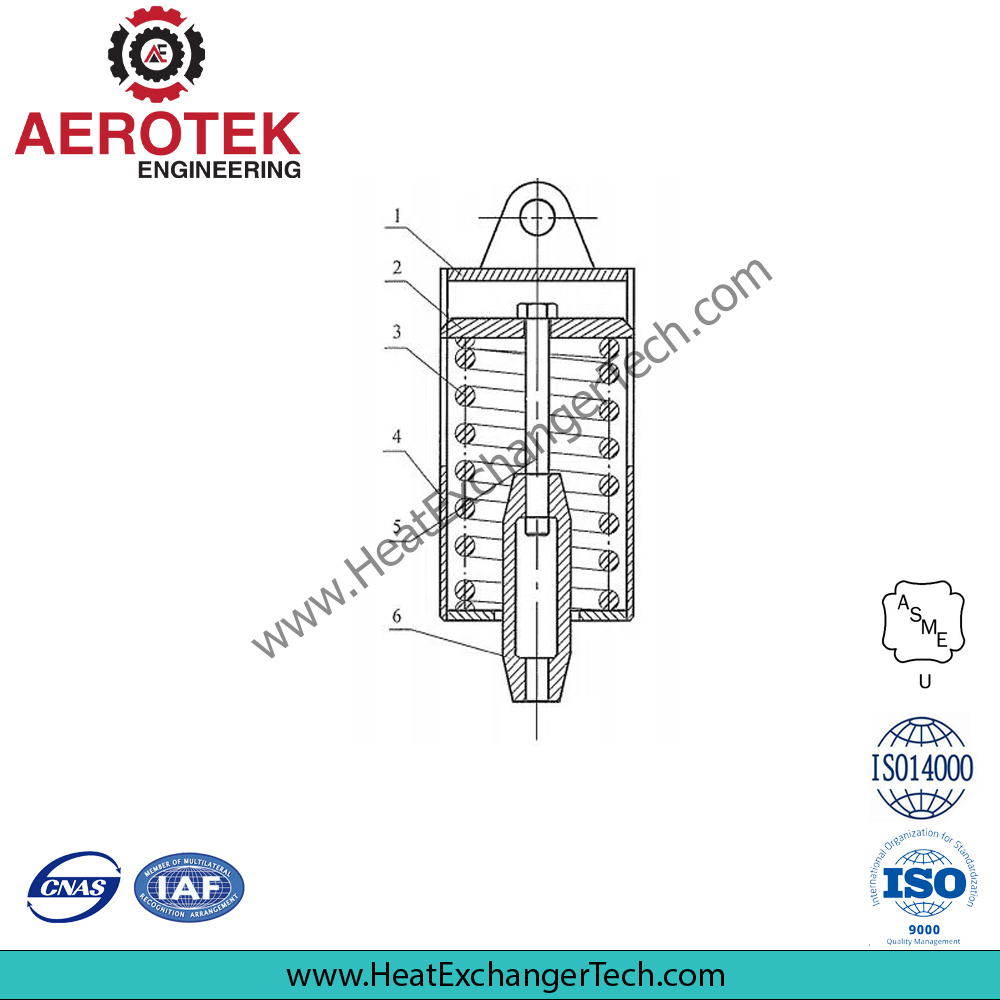

Structural drawing of variable spring support and hanger

Type of Variable Spring Support and Hanger:

Installation method, support type, and code of variable spring support and hanger

- Type Code: Installation method and support and hoisting form

- A: The top plate of the support and hanger is connected with the rooting beam with an upper threaded suspender to suspend the gelow pipes and equipment.

- B: The top plate of the support and hanger is connected with the rooting beam with a single ear plate to suspend the gelow pipes and equipment.

- C: The top plate of supports and hangers shall be connected with the rooting beam with double ear plates to suspend the gelow pipes and equipment.

- D: The base plate of the support and hanger is placed on the supporting member to suspend the pipes and equipment below and adjust it upward.

- E: The base plate of the support and hanger is placed on the supporting member to suspend the pipes and equipment below and adjust it downward.

- F1: The bottom plates of supports and hangers are placed on the supporting members to support the above pipes and equipment (with ordinary load plate)

- F2: The bottom plates of supports and hangers are placed on the supporting members to support the above pipes and equipment (with roller load plate)

- G: The supports and hangers are connected in parallel; the top plate is connected with the rooting beam with a single-threaded pull rod, to suspend the gelow pipes and equipment.

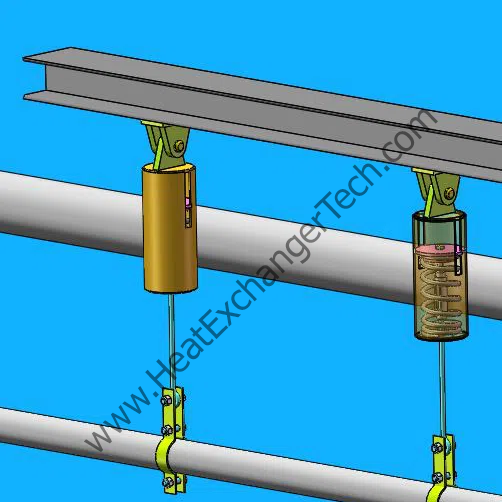

Installation of variable spring supports and hangers:

The positioning load before delivery is the installation load, which is marked with a blue arrow. The load during operation after installation is the working load, and the position is marked with a red arrow.

According to the pipe rack number, pipeline number, specification, and model install according to the above figure.

After the installation is completed and the hydrostatic test is qualified, remove the positioning block

Send Inquiry