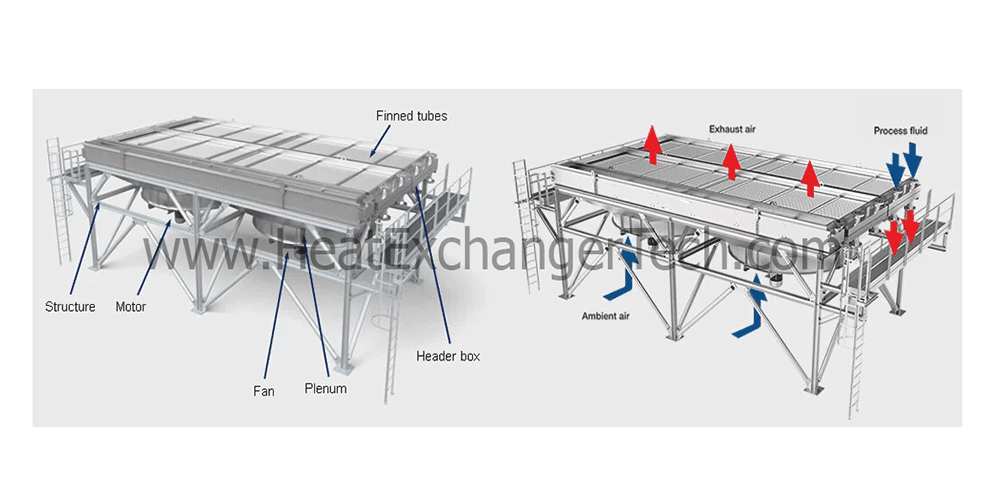

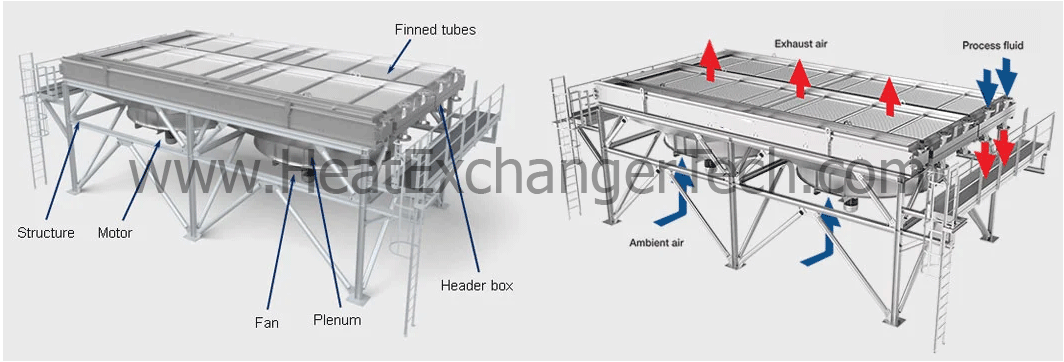

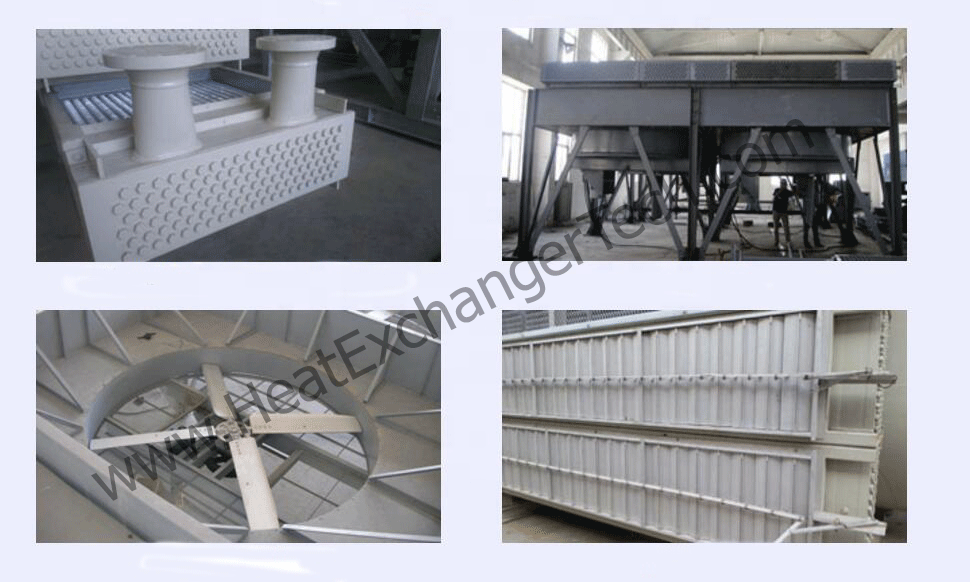

The air-cooled heat exchanger (air cooler for short) is a heat exchange device that uses ambient air as the cooling medium and the fan forces air to cross sweep the finned tube so that the high-temperature process fluid in the tube can be cooled or condensed. The air cooler unit is composed of a fin bundle, fan, frame, shutter, maintenance platform, ladder, and other auxiliary parts.

Using natural air as a cooling medium saves precious water resources, reduces the discharge of industrial sewage, and protects the natural environment. Air cooler can be used for cooling or condensation in oil refining, petrochemical tower top steam condensation, cooling of reflux oil and bottom oil,

cooling of various reaction products, cooling of circulating gas and condensing of steam turbine exhaust.

Product Features:

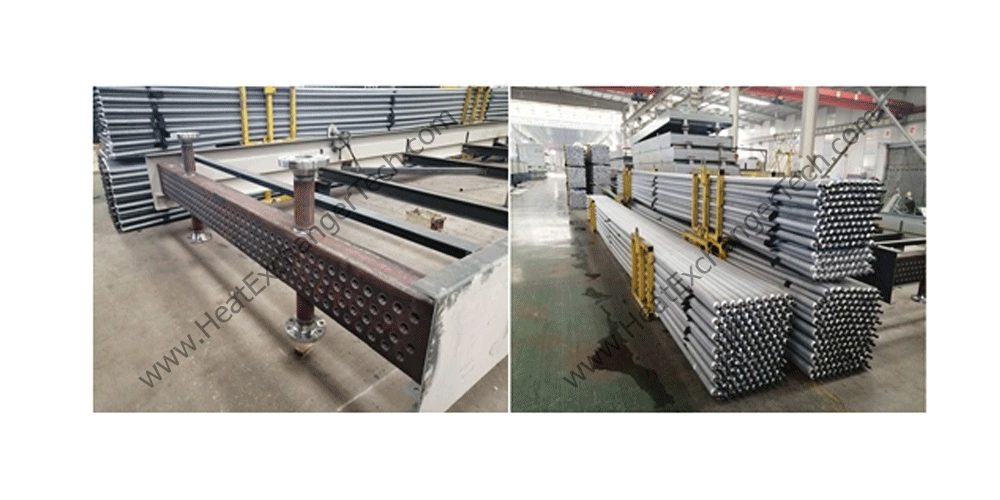

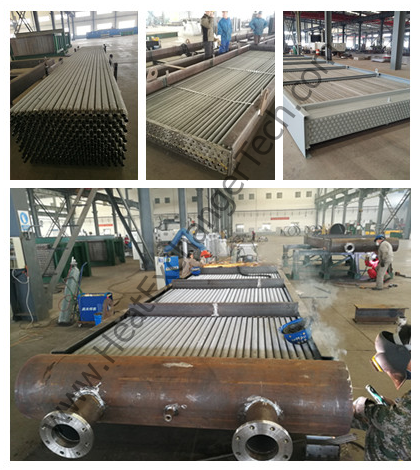

- Extend heat transfer area by using fin tubes

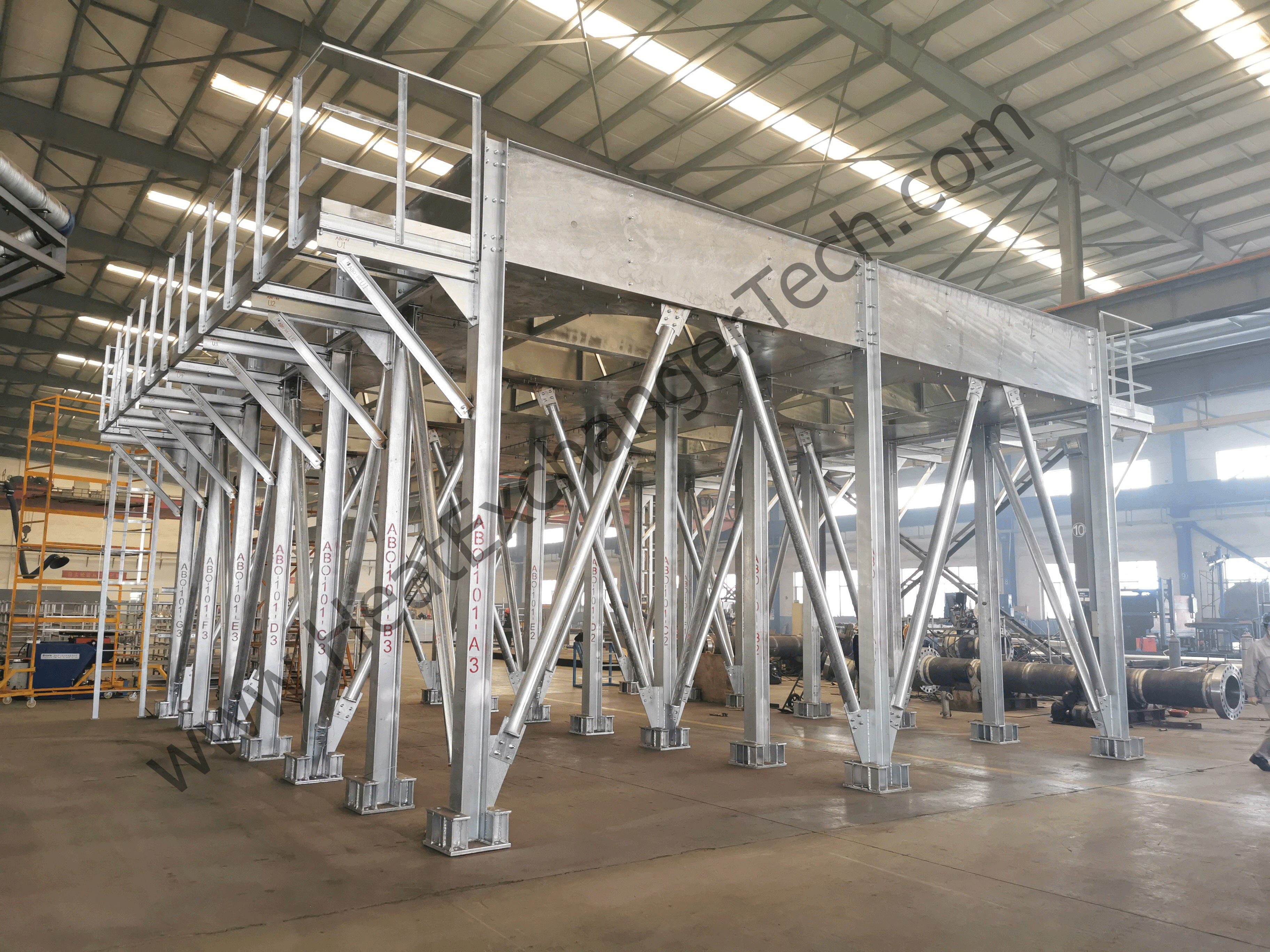

- The tube bundle adopts a modular design, which can be combined by multiple modules

into a large thermal load condition, easy to install and transport. - Even distribution of air, less noise

- Taking the ambient air as the cooling medium, saving precious water resources,

reducing discharge PF waste industrial water, protecting the environment, less corrosion,

long service life.

Advantages of air cooler:

- Environmental Advantages

•There is no thermal or chemical pollution to the environment

•It is especially suitable for use in places where water is scarce. - Cost Advantage

•Unrestricted site selection

•Air can be obtained at will, no auxiliary equipment and costs are required - Maintenance Advantages

•The maintenance cost of the air cooling system is 20-30% of the water cooling system;

•The air is less corrosive, does not require descaling and cleaning, and has a long service

life.

Send Inquiry