The preheater can make full use of the heat in the kiln, reduce the heat consumption of clinker firing, and reduce the area occupied by the firing equipment.

Product overview:

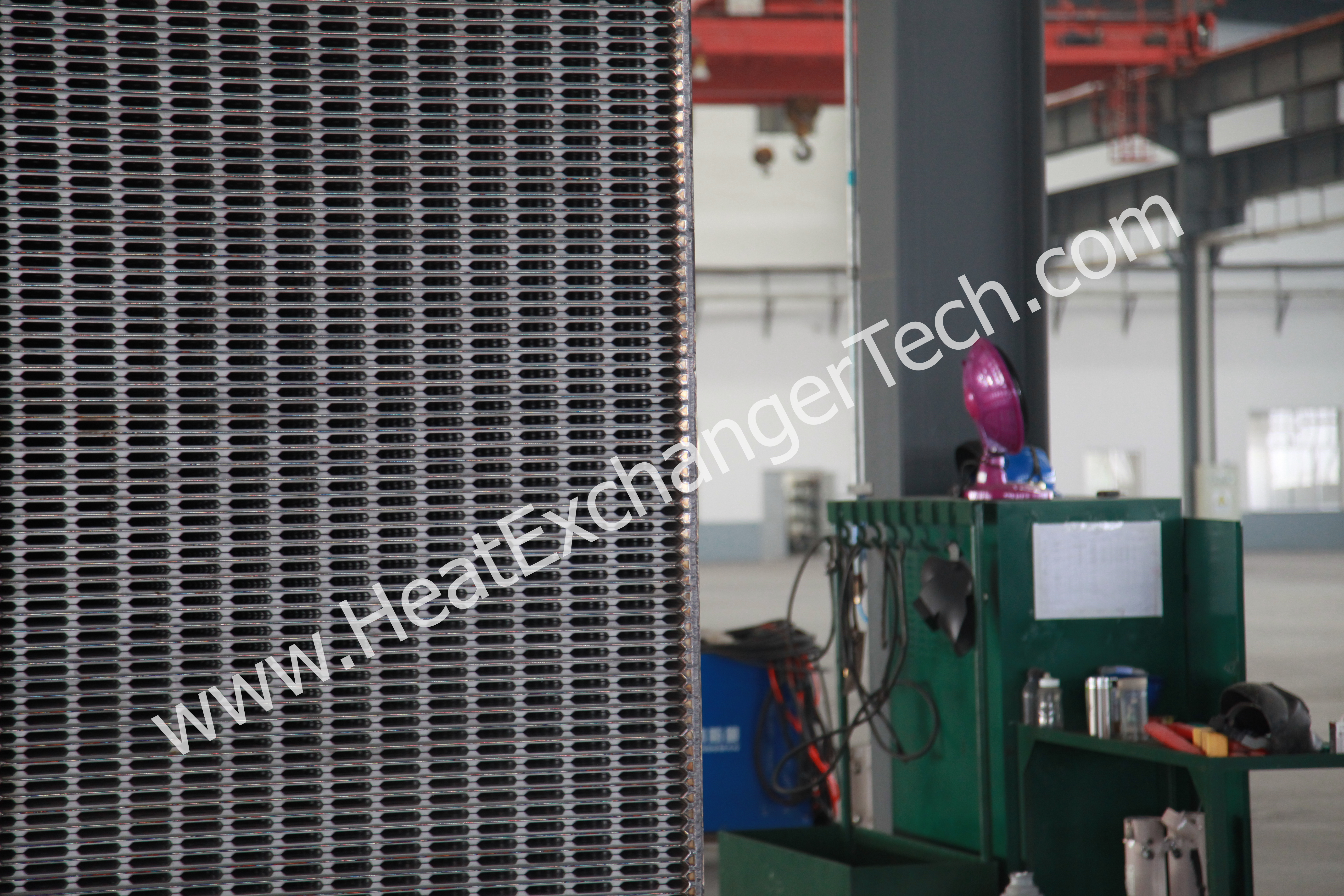

- Product Name: High Temperature Desulfurized Flue Gas Heat Exchanger

- Brand: AEROTEK

- Structure Type: Plate type

- Plate Material: SS410,304, 316, 316L, 2205, SMO254,etc.

- Plate Thickness: 0.6~2mm

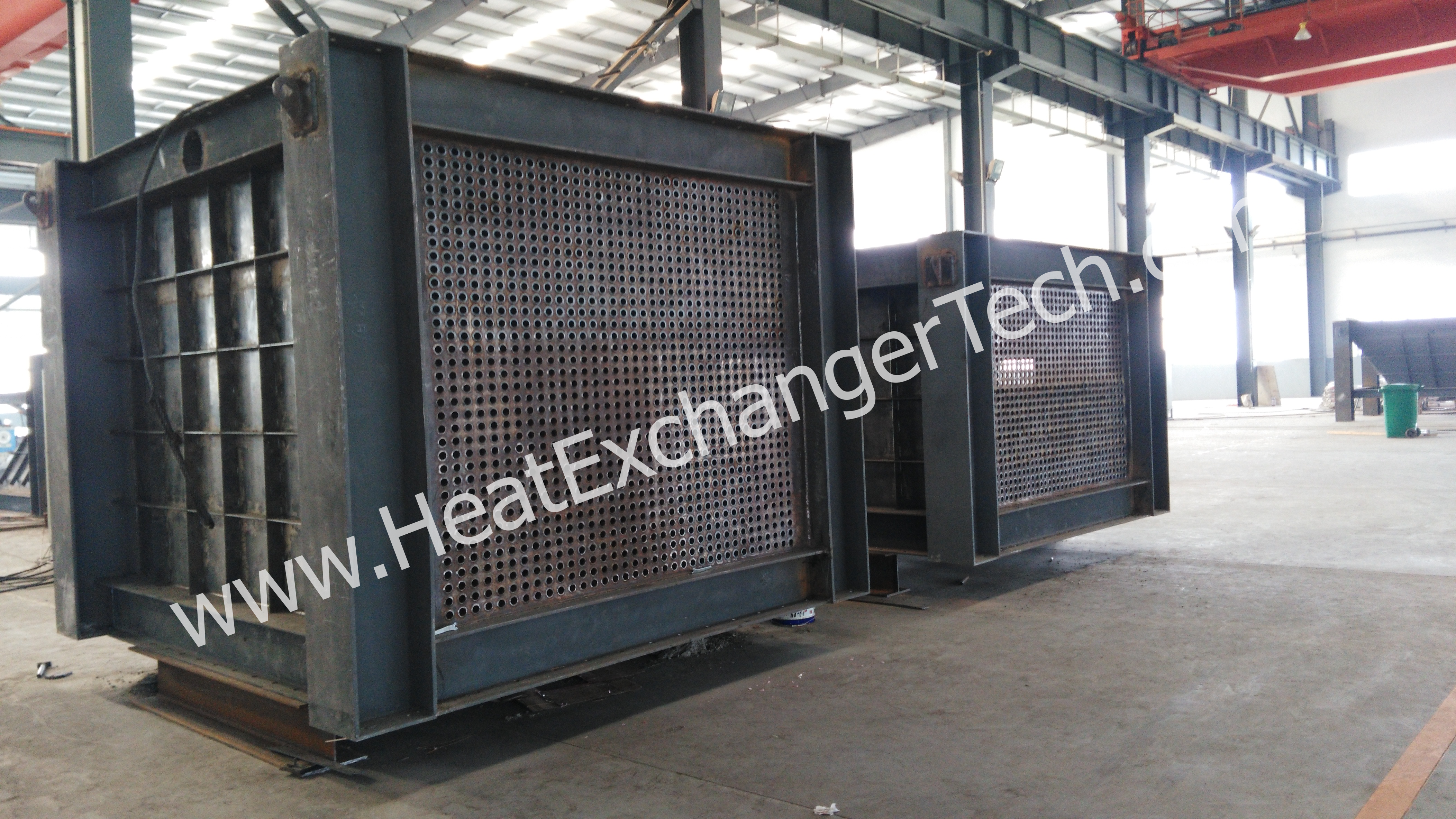

- Casing Material: Carbon steel or stainless steel

- Design Temperature: 900℃

- Design Pressure: 0.1 Mpa

- Size: Depending on the order

- Design: Standard ASME Sec. VIII Division I

- Lead Time: Can be Negotiated

- Production Capacity: 300 tons per month

- Function: Preheat purified gas

Description of Desulfurized Flue Gas Heat Exchanger:

The desulfurized flue gas heat exchanger is a kind of equipment that preheats the purified gas with the waste heat extracted from flue gas. By doing so, the temperature of the desulfurized flue gas is lifted for easier and smoother flow in the chimney and then released to the atmosphere, reducing environmental pollution.

Send Inquiry