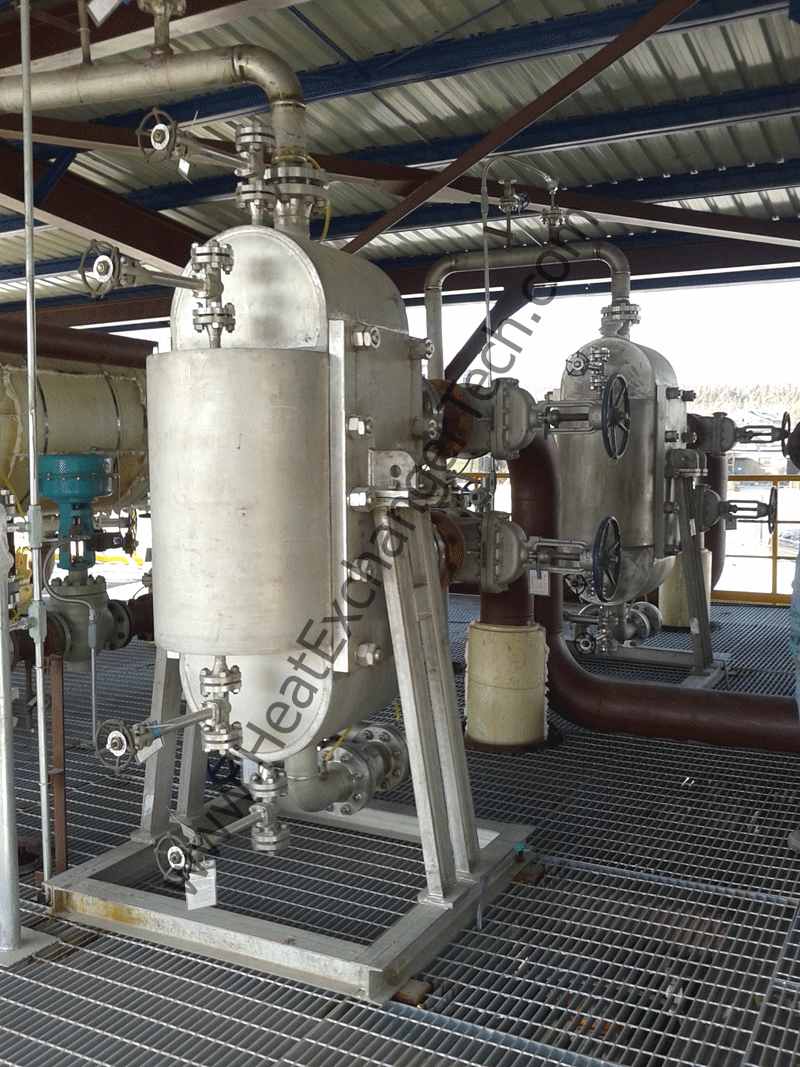

Our designed Plate and Shell heat exchangers combine the benefits of plate heat exchangers and tubular heat exchangers. Retaining the high working pressure and temperatures of tubular heat exchangers coupled with the high efficiency of plate heat exchangers; plate and shell heat exchangers provide unmatched performance for a wide range of applications. Our Plate and Shell heat exchangers are able to handle a wide range of thermal duties: evaporation, chemical processes, condensation, NH3 applications, heat recovery, liquid/liquid applications fuel oil heaters, and steam/liquid applications.

The Plate and Shell heat exchanger is available as a fully welded or a bolted solution, depending on your specifications. The heat exchanger features a fully welded plate pack making it well-suited for handling aggressive media, as well as high pressure and temperatures. The single-pass plate and shell heat exchanger is ideal for handling duties with low thermal requirements that need short plates for efficient heat transfer. For higher thermal requirements, the plate and shell heat exchanger can be designed as a multi-pass solution.

Benefits Include:

Reduced footprint compared with other heat exchanger designs, high heat transfer coefficient, reduced risk of fouling easy and cost-effective maintenance, and an excellent return on your investment.

Send Inquiry