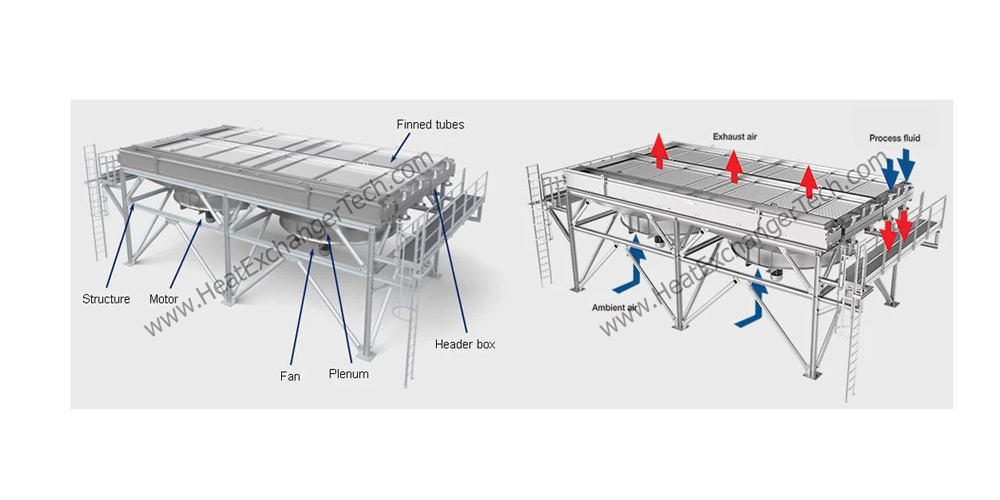

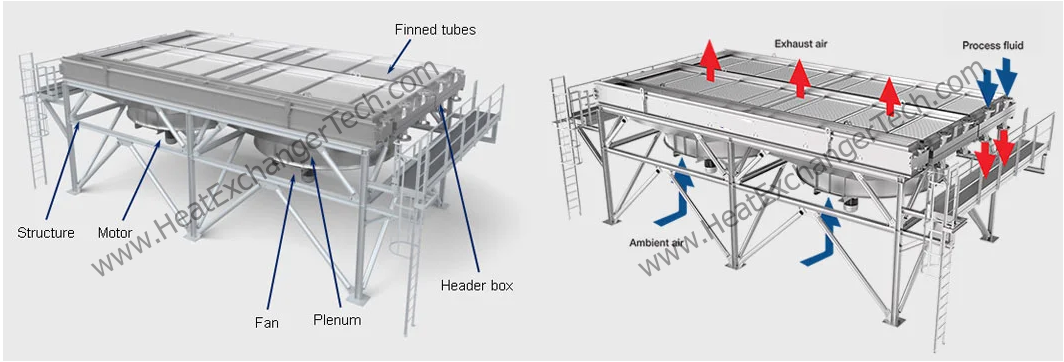

An air-cooled heat exchanger (air cooler for short) is a kind of heat exchange equipment that uses ambient air as a cooling medium and the fan forces the air to cross the finned tube to cool or condense the high-temperature process fluid in the tube.

Scope of Application:

It is mainly used in petroleum, chemical industry, metallurgy, and other air coolers. It has the advantages of large air volume, high efficiency, small vibration, low noise, and convenient maintenance.

There are different types of fans, such as high efficiency and energy saving, low noise, anti-corrosion, and so on. The air volume regulation mode of fans can be divided into self-regulation, semi self-regulation, and manual regulation; the cooling mode can be divided into blast type and induced draft type.

Product features:

- The finned tube is used to increase the heat transfer area.

- The tube bundle adopts a modular design, which can be combined with multiple modules to form a large heat load condition, which is convenient for installation and transportation.

- The air distribution is uniform and the noise is low.

- The use of natural air as a cooling medium can save valuable water resources reduce the discharge of industrial wastewater, protect the natural environment, reduce corrosion and prolong the service life of the equipment.

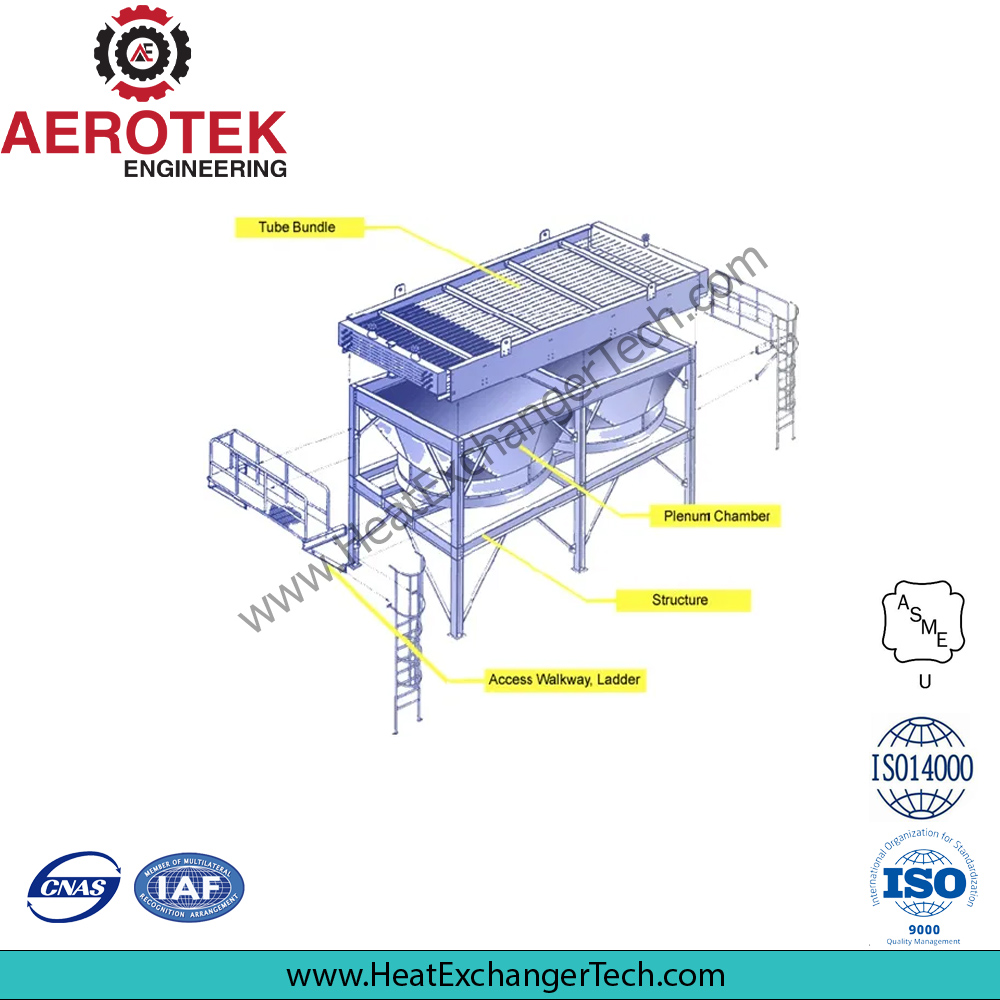

Main Structure:

Air coolers can be divided into the following different forms because of their different structure, installation form, cooling, and ventilation mode.

-

- According to the arrangement and installation form of the tube bundle, it can be divided into a horizontal air cooler and an inclined top air cooler.

- According to different cooling methods, it can be divided into dry air cooler and wet air cooler.

- According to different ventilation modes, it can be divided into forced ventilation air

cooler and induced ventilation air cooler

Application of Air Cooled Heat Exchanger:

Send Inquiry