We are offering all TEMA type (BEM, AEM, BES, AES, BET, BEU, AET) Shell and Tube Heat exchangers under ASME U Stamp, DNV & CE Certification.

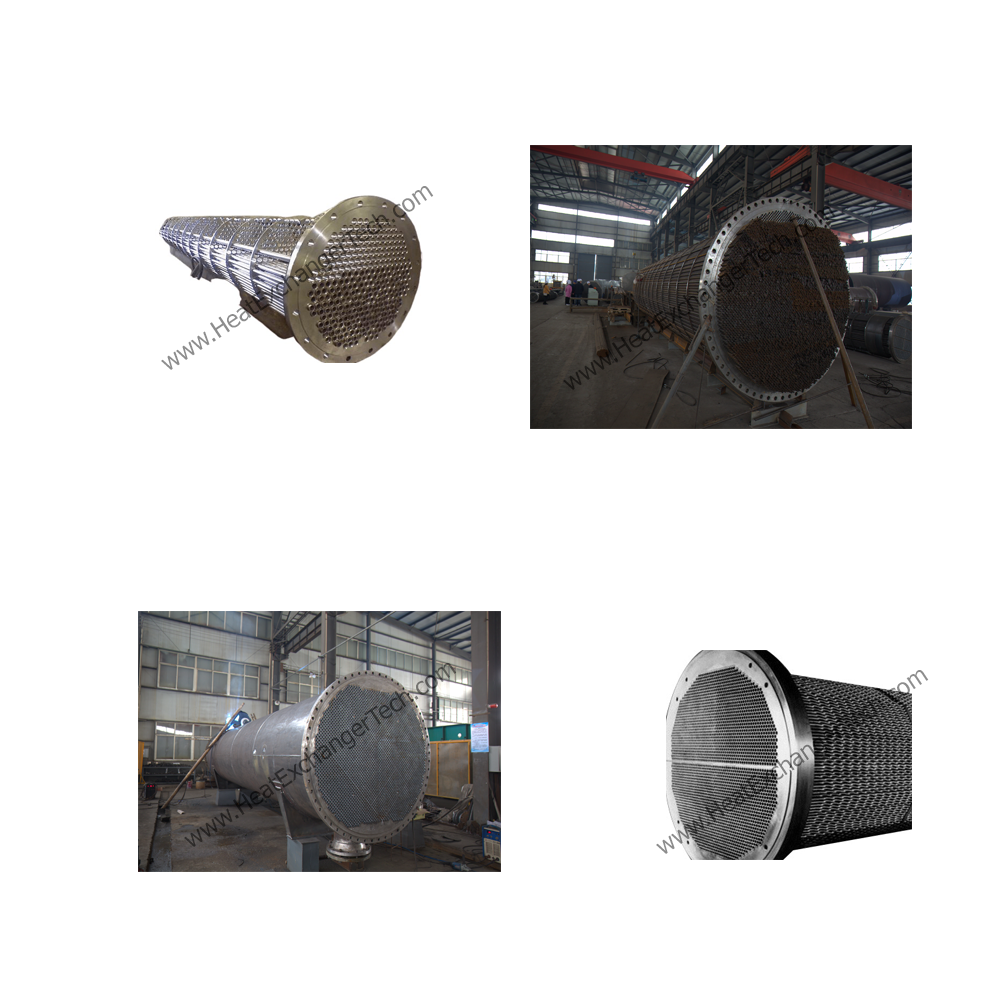

Shell and tube heat exchanger is composed of shell, heat transfer tube bundle, tube plate, and baffle plate and tube box. The shell is mostly cylindrical and is equipped with a tube bundle. Both ends of the tube bundle are fixed on the tube plate.

Working Principle of Tubular Heat Exchanger

A tubular heat exchanger, also named shell and tube heat exchanger, takes tube bundles as the heat transfer core. One fluid flows inside the tubes and the other fluid flows outside the tubes but inside a shell, thus forming crossflow to perform heat transfer.

This kind of tubular heat exchanger is the most common type in petroleum refineries and other chemical processes. The most significant feature of a tubular heat exchanger is the high pressure that it can withstand, which is several times higher than the plate type.

The fluids can be either liquids or gases flowing through on either the tube or the shell side. In order to meet the heat transfer efficiency, a large heat transfer surface is usually required, leading to the use of a large number of tubes.

Design of a Tubular Heat Exchanger

Typically, the ends of each tube are connected to plenums (sometimes called water boxes) through holes in tube sheets. According to the shapes of the tube, there are two kinds of tubes adopted: straight tubes and U-tubes, which are bent in the shape of a U.

U-tube heat exchanger

In nuclear power plants, large heat exchangers called steam generators are usually designed into two-phase with U-tubes. They are used to boil water recycled from a surface condenser into steam to drive a turbine to produce power. Most shell-and-tube heat exchangers are either 1, 2, or 4 pass designs on the tube side. This refers to the number of times the fluid in the tubes passes through the fluid in the shell. In a single-pass heat exchanger, the fluid goes in one end of each tube and out the other.

Straight Tube Heat Exchanger

Tubular heat exchangers working as surface condensers in power plants are often 1-pass straight-tube heat exchangers. Two and four pass designs are common because the fluid can enter and exit on the same side. This makes construction much simpler. There are often baffles directing flow through the shell side so the fluid does not take a shortcut through the shell side leaving ineffective low flow volumes. Baffles are typically attached to the tube bundle rather than the shell so that the bundle still can be removed for easy maintenance.

Countercurrent heat exchangers are most efficient because they allow the highest log mean temperature difference between the hot and cold streams. Many companies however do not use two-pass heat exchangers with a u-tube because they can break easily in addition to being more expensive to build. Often multiple heat exchangers can be used to simulate the counter-current flow of a single large exchanger.

Tabular Heat Exchanger Tube bundle Material

To be able to transfer heat with high efficiency and safety, the tube material should have good thermal conductivity and be strong enough to bear the thermal stresses. So strong, thermally-conductive, corrosion-resistant, high-quality tube materials have to be used for the construction of a tube bundle.

The tubes we most widely used are carbon steel, stainless steel, Hastelloy, and titanium. Design and Construction Standard

- Standards of the Tubular Exchanger Manufacturers Association (TEMA), 10th edition, 2019

- ASME Boiler and Pressure Vessel Code, Section VIII, Division 1

Send Inquiry