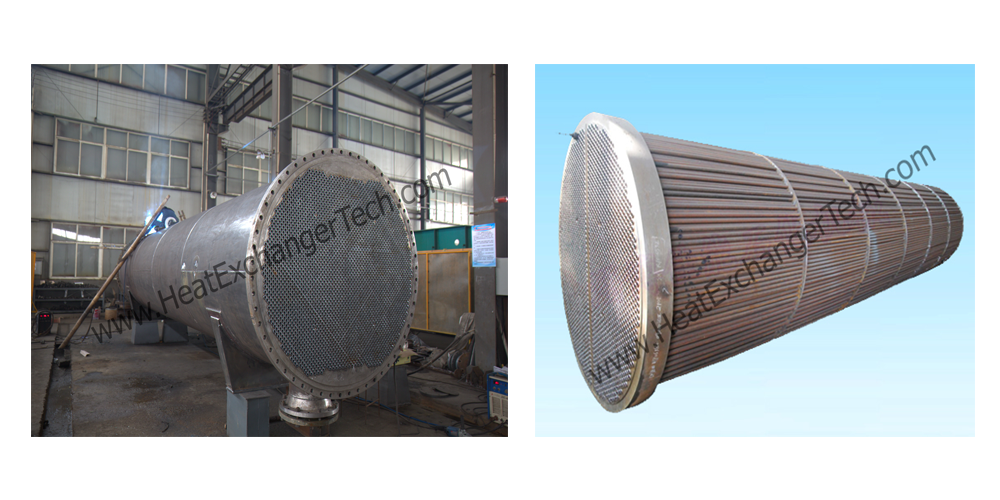

We are offering all TEMA type (BEM, AEM, BES, AES, BET, BEU, AET) Shell and Tube Heat exchangers under ASME U Stamp, DNV & CE Certification.

Shell and tube heat exchanger is made to transfer energy from high fluid heat transfer to the lower temperature fluid, the fluid temperature can reach the indexes of the flow rules, so as to meet the needs of process conditions, as well as one of the main equipment of improving energy efficiency. The heat exchanger industry deals with nearly 30 kinds of industries, such as HVAC, pressure vessels, and medium water treatment equipment, which form the industrial chain.

Industrial Application:

The Shell and tube heat exchanger industry in china has achieved remarkable results in energy saving and efficiency, increasing heat transfer efficiency, reducing heat transfer area, lowering pressure drop, and improving thermal strength of the plant-based on petroleum, chemical, electric power, metallurgy, shipbuilding, machinery, food,

pharmaceutical, and other industries to stable demand growth of the heat exchanger.

It’s the special equipment for medium cooling, heating, pre-heating, condenser, refrigeration, etc.

Products Description:

Advantages:

Low Maintenance Costs with Tubular Heat Exchangers

Since there is almost no need for spare parts (it is a completely welded construction). Easy inspection and disassembly In order to get better access to the tube sheet and the inner tubes, we can consider flanged tube sheet designs as well as connections in all the interconnections/bends between the modules.

High Working Pressure

As there are no gaskets and the heat exchangers are completely welded, the design pressure can be over 100 barg.

Processing of Particulate or Fiber Products is the diameter of the inner tubes determined by the percentage and shape and size of the solids.

Easy to Enlarge

Due to its modular design. It is relatively simple to add some modules in series with the aim to increase the thermal duty and the temperature difference. Likewise, in case of being necessary to increase the process flow rate, some lines in parallel can be arranged by means of manifolds that split the product or service flow. We can provide different kinds of materials for your industrial application. Like stainless carbon steel, steel 304, 316L, duplex steel 2205, 310s, titanium (1, 2, 9, 10), Hastelloy, etc.

Send Inquiry